Drop Testing of Packaged Gases

Impact protection for Industry

Global distributors of packaged gases, such as BOC, Air Products and Air Liquide, supply gases to the industrial, energy, technology and healthcare markets. Several million cylinders are in distribution on the UK’s roads and the consequences of a structural failure can be serious. Most gases are a fuel and leaks can result in a combustible substance. To ensure safe and reliable operation, particular measures are taken in the design of cylinders and equipment.

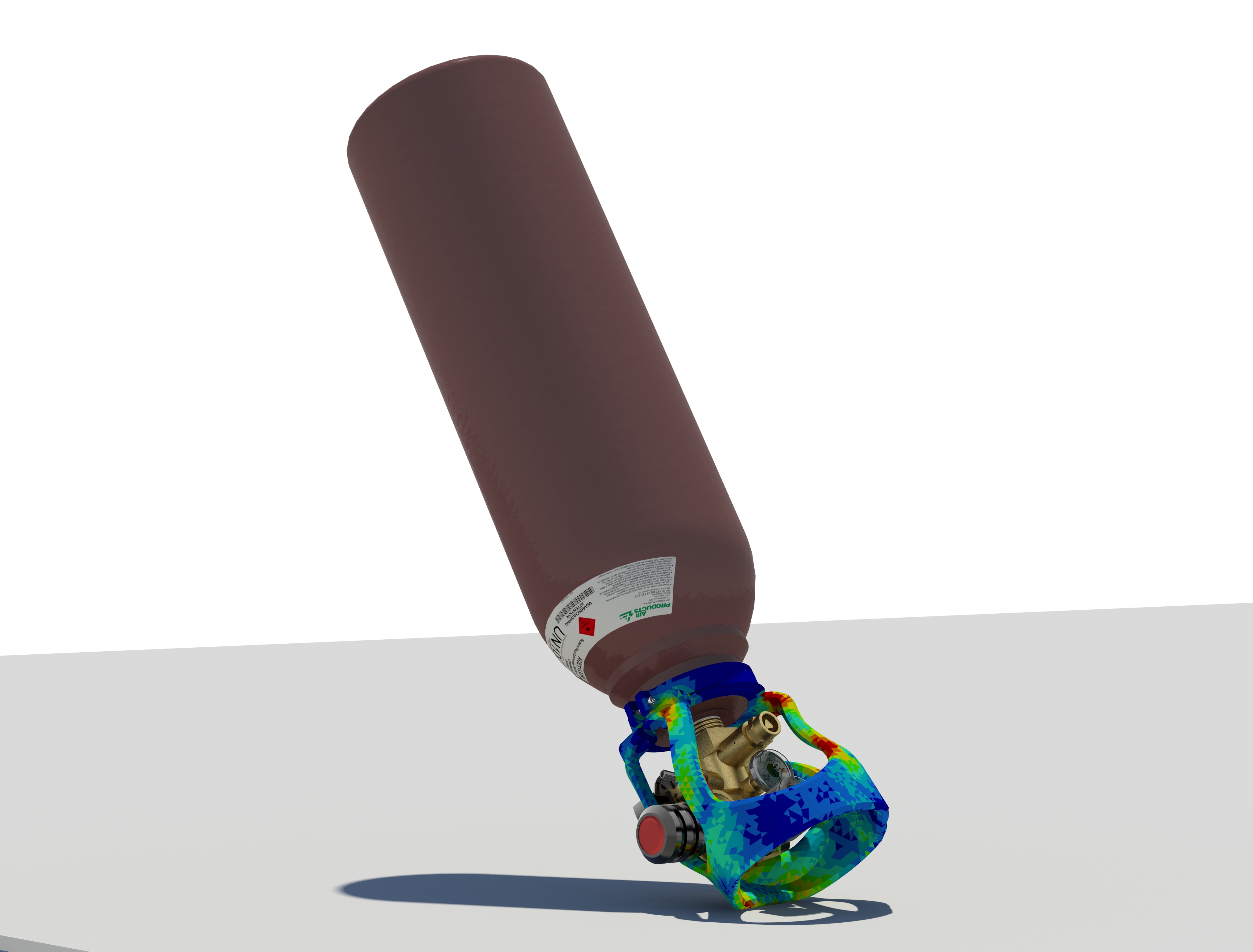

The European standard BS EN ISO 11117:2008 lays out the requirements for valve protection and the drop tests for the assessment. Cylinders are drop tested from a height of 1.2m and tested at -20ºC, ambient and +65ºC as these assemblies can be subject to a wide range of environmental conditions. The certification body can drop the assembly at any angle around the cylinder axis.

Simpact have pioneered the drop test modelling of packaged gases and have developed models that can be used for the effective design of polymeric guards. This includes the use of an SPH technique to represent the sloshing of the fluid within the cylinder.

Through research with WMG (Warwick University) and our Polymer Innovation Programme, Simpact gain access to the relevant mechanical testing equipment required to obtain the material mechanical properties for the impact resistant polymers used for the manufacture of protective guards and the representative stress-strain data required for robust impact simulation.

In 2015 the GCE Group came to Simpact - a leading manufacturer of equipment for medical gas supply, laboratories and industry. Simpact designed a new protective guard for their combilite valve. This work is captured in our Case Study 'An Introduction to SMART Product Development in the Packaged Gas Industry' which featured in an Editorial in the June 2016 edition of the Gasworld Magazine.